Product Description

| Model NO. | Custom Parts | Application | Fastener, Auto and Motorcycle Accessories, Hardware Tool, Machinery Accessory |

| Standard | GB, EN, China GB Code, JIS Code, TEMA, ASME | Surface Treatment | Anodizing |

| Production Type | Mass Production | Machining Method | CNC Machining |

| Material | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron | Drawing Type | Dwg, Dxf, Step, Iges, Pdf, STP, etc. |

| Tolerance | +/-0.002mm, or Customized | Roughness | Ra0.2-Ra3.2 , or Customized |

| Surface Finish | Anodization, Plating, Passivation, Polish, Brush | Colors | Blue, Red, Black, Gold, Orange, Green, Gray, White |

| Sample Service | Available | Part Name | CNC Machining Parts |

| Service | Machining, Assembly, Surface Treatment, etc. | Dimensions | Customized |

| Lead Time | 1-4 Weeks Depends on Requests | MOQ | 1 PCS, But Over 100PCS Is a Price Break Point |

| Machining Capability | 3,4,5 Axis CNC Milling, CNC Turning, Sheet Metal | Price | Negotiable as Per Request |

| Transport Package | Foam, Carton | Specification | Custom dimension |

| Trademark | Custom | Origin | China |

| HS Code | 84799 0571 0 | Production Capacity | 50000PCS |

Product Description

| Parts Application | Industrial Parts, Bikes, Engine parts, Robotic Parts, Decoration, BMX, EDC, yoyo, CHINAMFG parts, Electronics aluminum parts, Toys parts, Gears, Car parts, 4X4 parts, Medical Parts. Oil industry parts. Audio equipment parts, Musical Instrument parts |

||

| Machining Tolerance | The best tolerance is +/-0.002mm, can do as per your request. | ||

| Roughness | Ra0.2-Ra3.2, (as per specification) | ||

| Quotation | Need to know material, quantity, surface treatment, and another special request before sending you a quotation | ||

| Software Available | CAD, CHINAMFG Works, UG, CAD/CAM/CAE, PDF. | ||

| Surface Finish | Matte, Glossy, Tumbling, Smooth, beadblasting. | ||

| Surface Treatment | Anodization, Plating, Passivation, Polishing, Brushing. | ||

| Materials Available | Aluminum, Brass, Copper, Stainless Steel, Titanium, PVC, ABS, PEEK, Nylon, Delrin, Acrylic, Steel | ||

| Inspection instruments | Height Gauge, CMM, Caliper, Electronics Scale, Micrometer/Microcaliper, Gage Blocks, Pin Gauge. | ||

| Service Available | 1. CNC machining, CNC milling, CNC turning, Sheet Metal, Laser cutting, 2. Assemble (Using press fit or other technology), 3. Packing for “ready to sale” products, 4. Customized Packaging, 5. Relative accessory purchasing. |

||

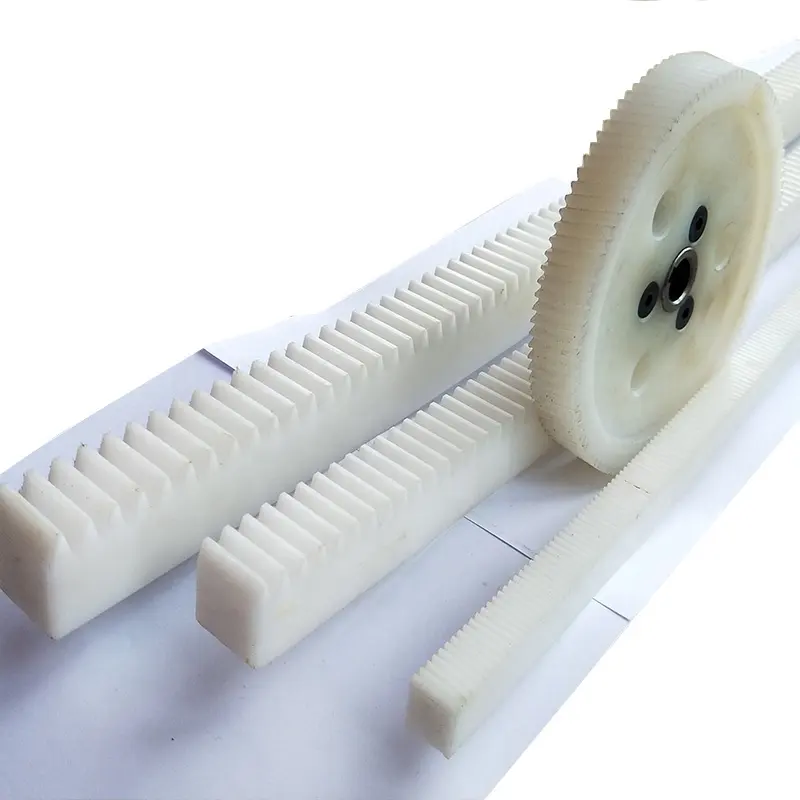

Sample Parts Show

Why Choose us

Our Equipments

Test Report Sample

Certifications

Our Package

FAQ

| Q1. Are you a genuine manufacturer? | |||

| Yes, all the products are produced in our ISO9001:2015 certified factory; We are also a company registered by China Customs with the right to export and import. | |||

| Q2. What should I offer to get your quotation? | |||

| Please offer us your detailed information for the product, such as drawings with 2D/3D by software Pro/E, Auto CAD, SolidWorks, UG etc; as well as materials, surface treatment, quantity, package. Any special requirements should be highlighted especially for tolerance. | |||

| Q3. Can we get a complete product besides CNC parts? | |||

| To some extent, yes, we can. But firstly we need assess feasibility. | |||

| Q4. What’s your top process tolerance? | |||

| Now our top process tolerance is ± 0.005mm. | |||

| Q5. What are your sample policy and trade/payment terms? | |||

| We can offer the free samples with total value less than USD10; while the buyers should bear shipping cost and import VAT. | |||

| Ex-works, FOB ZheJiang /HangZhou, CIF etc. would be OK for us. | |||

| As for the payment, small value is recommended by Paypal or Western Union; larger amount by T/T, 50% as deposit, 50% before shipment. | |||

| Q6. How about the warranty? | |||

| The warranty is for 1 year. As you know, our CNC parts have a long lifespan except for damaged by operating inappropriately. | |||

| Q7. What’s your policy for RMA? | |||

| All defective products should be confirmed by us based on the customers’ RMA list and photos first, then we’d like to refund the money or compensate the goods by free of charge accordingly. | |||

| Q8. I want to keep our design in confidence; can we CHINAMFG NDA? | |||

| Sure, to protect customers’ profit is our obligatory responsibility, signed NDA would be valid to both of us. | |||

| . | |||

| What benefit we can get from you? | |||

| 1) Competitive price | |||

| 2) High quality control : 100% full inspection before shipment | |||

| 3) High precision, tolerance can be ± 0.005mm | |||

| 4) Fast lead time (5-7days for samples, 12-15 days for mass production) | |||

| 5) Non-standard//OEM//customized service provided | |||

| 6) No MOQ, small QTY is acceptable. | |||

| 7) Factory ISO 9001 certification, ROHS material used | |||

| 9) Professional export packing: separate Blister plastic box or Bubble Wrap/Pearl Wool +Carton+ Wooden Case, keep no scratch and damage |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard: | GB |

|---|---|

| Surface Treatment: | Anodizing, Painting, Phosphating, Passivation… |

| Customization: | Yes |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What types of materials are typically used for rack and pinion components?

Various materials are used for manufacturing rack and pinion components, depending on the specific application requirements and operating conditions. The choice of materials is crucial to ensure the performance, durability, and reliability of the rack and pinion system. Here are some types of materials that are typically used for rack and pinion components:

- Steel Alloys: Steel alloys are commonly used for rack and pinion components due to their excellent strength, hardness, and wear resistance. Different types of steel alloys, such as carbon steel, alloy steel, or tool steel, may be employed based on the desired properties and load requirements. Steel offers good durability and can withstand heavy loads, making it suitable for various industrial applications.

- Stainless Steel: Stainless steel is another popular material choice for rack and pinion components, especially in applications where corrosion resistance is critical. Stainless steel offers excellent resistance to rust, oxidation, and chemical corrosion, making it suitable for environments with high humidity, moisture, or exposure to corrosive substances. It provides good strength and durability while maintaining a clean and aesthetic appearance.

- Cast Iron: Cast iron is sometimes used for rack and pinion components, particularly in larger or heavier-duty applications. Cast iron possesses high compressive strength, good vibration damping properties, and excellent wear resistance. It can handle substantial loads and is suitable for applications where noise reduction and stability are important factors.

- Non-Ferrous Alloys: Non-ferrous alloys, such as bronze or brass, are utilized in specific cases where their unique properties are advantageous. These alloys offer good corrosion resistance, high machinability, and low friction characteristics. They are often chosen for applications where self-lubrication or compatibility with softer mating materials is required.

- Plastics and Polymers: Certain plastic materials and polymers, such as nylon, acetal, or polyethylene, are used for rack and pinion components in specific applications. These materials offer advantages such as low friction, self-lubrication, lightweight, and resistance to chemicals or moisture. Plastic components can contribute to quieter operation, reduce the need for external lubrication, and provide cost-effective solutions in certain environments or applications.

- Specialized Alloys and Coatings: In some demanding applications, specialized alloys or coatings may be employed to enhance the performance of rack and pinion components. For example, hardened or heat-treated alloys can provide increased strength and durability. Coatings such as chrome plating or nitriding can improve wear resistance and reduce friction. These materials and coatings are typically chosen for specific requirements, such as high-load capacities, extreme operating conditions, or extended service life.

It is important to note that the selection of materials for rack and pinion components depends on various factors, including load capacity, speed, environmental conditions, cost considerations, and specific application requirements. Engineers and manufacturers evaluate these factors to determine the most suitable material or combination of materials that will optimize the performance and longevity of the rack and pinion system.

How do rack and pinion systems handle variations in temperature and humidity?

Rack and pinion systems are designed to handle variations in temperature and humidity, ensuring their proper functioning and longevity in diverse environmental conditions. Here’s a detailed explanation:

Temperature Variations:

Rack and pinion systems are typically constructed using materials that can withstand a wide range of temperatures. Some common materials used for rack and pinion components include steel, stainless steel, aluminum, and various engineering plastics. These materials are chosen for their thermal stability and resistance to expansion or contraction due to temperature changes.

When exposed to temperature variations, rack and pinion systems can experience dimensional changes. However, the materials used are selected to minimize the effects of thermal expansion or contraction. Manufacturers consider the coefficient of thermal expansion of the materials and design the system with appropriate tolerances to accommodate temperature-related dimensional changes. This helps maintain the system’s accuracy and functionality over a range of operating temperatures.

In extreme temperature conditions, lubrication becomes an important consideration. High temperatures can cause lubricants to degrade, leading to increased friction and wear. To address this, specialized lubricants that can withstand elevated temperatures are used in rack and pinion systems operating in high-temperature environments. Additionally, regular maintenance and lubrication checks are recommended to ensure optimal performance and to mitigate any adverse effects of temperature variations.

Humidity and Moisture:

Humidity and moisture can affect the performance and durability of rack and pinion systems, particularly if the system is exposed to excessive moisture or operates in highly humid environments. Here are some measures taken to address these challenges:

1. Material Selection: The materials used in rack and pinion systems are often chosen for their resistance to corrosion and moisture absorption. Stainless steel, for example, is commonly used due to its excellent corrosion resistance. Similarly, certain types of engineering plastics are less susceptible to moisture absorption, making them suitable for humid environments.

2. Protective Coatings: Applying protective coatings on rack and pinion components can help enhance their resistance to moisture and corrosion. Coatings such as zinc plating, chrome plating, or specialized corrosion-resistant coatings provide an additional barrier against moisture penetration and prolong the system’s lifespan.

3. Sealing and Gasketing: Rack and pinion systems can be designed with sealing mechanisms or gaskets to prevent moisture ingress. Seals and gaskets are placed at critical points, such as the gear meshing area or the housing joints, to create a barrier against moisture and contaminants. These seals help maintain the integrity of the system, reduce the risk of corrosion, and ensure consistent performance even in humid conditions.

4. Regular Maintenance: Regular maintenance practices, including cleaning, inspection, and lubrication, are essential for rack and pinion systems exposed to humidity. Cleaning the system to remove any accumulated dirt or moisture, inspecting for signs of corrosion or wear, and applying appropriate lubrication can help mitigate the effects of moisture and ensure the system’s optimal performance and longevity.

By incorporating suitable materials, protective coatings, sealing mechanisms, and maintenance practices, rack and pinion systems can effectively handle variations in temperature and humidity. These measures help maintain the system’s accuracy, reliability, and durability, even in challenging environmental conditions.

What is a rack and pinion system, and how does it work?

A rack and pinion system is a mechanism used to convert rotational motion into linear motion. It consists of two main components: a rack and a pinion. The rack is a linear gear with teeth along its length, while the pinion is a small gear with teeth that mesh with the rack. Here’s a detailed explanation of how a rack and pinion system works:

- The pinion, which is the smaller gear, is connected to a rotary motion source such as an electric motor or a manual crank.

- As the pinion rotates, its teeth engage with the teeth on the rack, causing the rack to move in a linear direction.

- The linear motion of the rack can be either back-and-forth or unidirectional, depending on the design and application.

- The teeth on the pinion and rack mesh together tightly, ensuring a positive and efficient transfer of motion.

- By varying the rotational speed and direction of the pinion, the linear motion of the rack can be controlled and adjusted.

- The rack and pinion system can be used to achieve various mechanical functions, such as linear actuation, positioning, or power transmission.

- Depending on the application, additional components such as guides, bearings, and support structures may be incorporated to enhance the system’s stability and performance.

- Rack and pinion systems are commonly used in a wide range of applications, including steering systems in automobiles, CNC machines, robotics, elevators, and other mechanisms that require precise linear motion.

The rack and pinion system offers several advantages, including simplicity, high efficiency, compactness, and the ability to convert rotational motion into linear motion with a relatively high degree of precision. However, it’s important to note that the system may generate some backlash or play due to the clearance between the teeth, which can be minimized through proper design and manufacturing techniques.

editor by CX 2024-04-12