Product Description

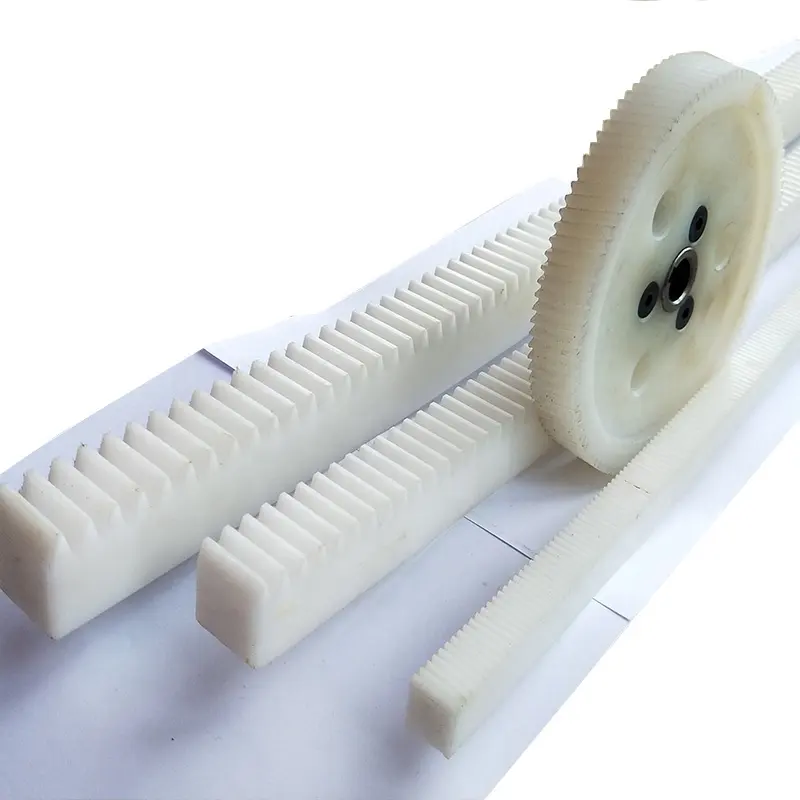

High Precision Gear Rack and Pinion for Construction Hoist Use Construction Spare Parts

Product Description

| Material | Steel 45# | Shape | Rack |

| Scope of application | SC200 SC100 | Tooth height | 60mm |

| Number of teeth | M8-1508 | Tooth width | 8MM |

| Tooth line shape | Spur gear | weight | 24KG |

Certifications

Packaging & Shipping

FAQ

High Precision Gear Rack and Pinion for Construction Hoist Use Construction Spare Parts

1. What are your main products?

We produce Construction Hoist (also called construction elevator, construction lift) and spare parts of it.

2. Are all Construction Hoist the same from all Vendors & Manufacturers?

Our High rise building construction hoist with VFD for lifting materials and passengers have exported to Europe, Middle and southern America, most of Asia, and some countries from Africa, about 50 countries. We can well match European standards, Russia standards and America standards. We have technology for develope new design ability and we support many customer with good solutions to solve their construction site special vertical access problems.

3. Do your products have some certificates?

Yes. Our Construction Hoist have passed CE ,ISO Certificates.

4. What are the payment terms and the delivery time?

Payment terms are T/T and LC. We will ship the cargo within 20-30 days after receiving the 30% deposit.

5. Are you manufacturer or the trader?

We are manufacturer with 14 years maker experiences, have advanced production line and inspection device. Our Research and development team have got many praise from customers.

6. Will you develop distributor and sole agent?

Yes, should you have any interest to be our distributor and agent, please let us know in any ways. Sole agent is available depend on the sales turnover.

7. Where do you ship to and what countries have you done business in?

We provide quick and efficient shipping to countries all over the world from HangZhou port or other China port.

We have done business with customers in many countries, such as Mexico, Brazil, Korea, Malaysia, Thailand, India, Vietnam, Indonesia, UAE, Qatar, Kuwait,Saudi Arabia etc.

We will provide best price once confirmed the above. You can get our feedback within 12 hours !

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Service |

|---|---|

| Warranty: | 1 Year |

| Type: | Bucket Teeth |

| Application: | Hoisting Machinery |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with rack and pinion?

Working with rack and pinion systems requires careful attention to safety to prevent accidents and ensure the well-being of individuals involved. Here are some important safety considerations to keep in mind when working with rack and pinion:

- Proper Guarding: Ensure that the rack and pinion system is properly guarded to prevent accidental contact with moving parts. Install appropriate barriers, shields, or enclosures to restrict access to the rack and pinion assembly, especially in areas where there is a risk of entanglement or pinch points.

- Lockout/Tagout: Implement lockout/tagout procedures when performing maintenance, repair, or adjustment on the rack and pinion system. Lockout/tagout procedures involve isolating the power source and securing it with a lock or tag to prevent accidental energization or motion during work, protecting workers from unexpected movement or startup.

- Proper Installation: Ensure that the rack and pinion system is installed correctly according to manufacturer guidelines and industry standards. Improper installation can lead to misalignment, instability, or premature failure, posing safety risks. Follow proper procedures for mounting, alignment, and securing of the rack and pinion assembly.

- Maintenance and Inspection: Regularly inspect and maintain the rack and pinion system to ensure its proper functioning and identify any potential safety hazards. Check for signs of wear, damage, or loose components. Lubricate the system as recommended by the manufacturer to maintain smooth operation and prevent excessive friction or overheating.

- Load Limitations: Adhere to the load limitations specified by the manufacturer. Overloading the rack and pinion system can lead to excessive stress, premature wear, or failure, potentially resulting in accidents. Consider factors such as weight, distribution, and dynamic forces when determining the appropriate load for the system.

- Training and Awareness: Provide adequate training to personnel who will be working with or around the rack and pinion system. Ensure they understand the potential hazards, safe operating procedures, and emergency protocols. Promote awareness of the risks associated with the system and encourage a safety-conscious culture in the workplace.

- Environmental Considerations: Take into account the environmental conditions in which the rack and pinion system operates. Factors such as temperature, humidity, corrosion, or exposure to hazardous substances may affect the system’s performance and safety. Use appropriate materials, coatings, or protective measures to mitigate potential risks.

- Emergency Stop: Install an emergency stop mechanism that allows for immediate shutdown of the rack and pinion system in case of emergencies or hazardous situations. Clearly mark and communicate the location of the emergency stop controls to ensure quick and easy access when needed.

It is essential to consult the manufacturer’s documentation, safety guidelines, and applicable regulations when working with rack and pinion systems. By following proper safety practices, implementing appropriate safeguards, and promoting a safety-focused mindset, the risks associated with working with rack and pinion systems can be minimized, creating a safer working environment.

How do rack and pinion systems contribute to precise motion control?

Rack and pinion systems play a crucial role in achieving precise motion control in various applications. The inherent design and characteristics of rack and pinion mechanisms contribute to their ability to provide accurate and reliable motion control. Here’s a detailed explanation:

1. Direct and Efficient Power Transmission: Rack and pinion systems offer direct power transmission, meaning there are no intermediate components or linkages between the input and output. This direct connection allows for efficient power transfer without significant energy losses. As a result, the motion control system can respond quickly and accurately to input commands, enabling precise control over the position, speed, and acceleration of the driven load.

2. High Mechanical Advantage: Rack and pinion systems provide a mechanical advantage, especially in applications where linear force or torque needs to be converted. The gear ratio of the system determines the mechanical advantage, allowing for amplification or reduction of the input force or torque. By adjusting the gear ratio, the system can be optimized to achieve the desired level of precision and force transmission. The mechanical advantage enhances the system’s ability to overcome friction, resist external disturbances, and maintain positional accuracy.

3. Minimal Backlash: Backlash refers to the slight clearance or play between the teeth of the gears in a mechanical system. Rack and pinion systems are designed to minimize backlash, ensuring precise and repeatable motion control. The tight engagement of the gear teeth in a rack and pinion mechanism reduces backlash, resulting in minimal lost motion and improved accuracy. This characteristic is particularly important in applications that require precise positioning, such as CNC machines, robotics, or optical equipment.

4. Smooth and Continuous Motion: Rack and pinion systems can provide smooth and continuous motion due to the constant contact between the gear teeth. The teeth on the pinion gear mesh with the teeth along the rack’s length, resulting in a continuous transfer of motion. This continuous contact helps to eliminate jerks, vibrations, or hysteresis that could affect the precision of the motion control system. The smooth and continuous motion is vital for applications where precise speed control or smooth trajectory tracking is required.

5. High Positional Accuracy: Rack and pinion systems excel at achieving high positional accuracy. The linear nature of the motion provided by the rack allows for precise control over the position of the driven load. Combined with low backlash, the system can accurately maintain the desired position without significant deviation. This level of positional accuracy is critical in applications such as CNC machining, 3D printing, or metrology, where tight tolerances and precise positioning are essential.

6. Scalability and Flexibility: Rack and pinion systems offer scalability and flexibility, making them suitable for a wide range of applications. They can be designed and implemented in various sizes and configurations to accommodate different load capacities, travel distances, and speed requirements. The modular nature of rack and pinion systems allows for easy integration into different mechanical systems, making them adaptable to diverse motion control applications.

In conclusion, rack and pinion systems contribute to precise motion control through their direct power transmission, high mechanical advantage, minimal backlash, smooth and continuous motion, high positional accuracy, and scalability. These characteristics make rack and pinion mechanisms a popular choice in numerous industries, including robotics, automation, manufacturing, and automotive, where precise and reliable motion control is vital.

In which industries are rack and pinion systems commonly used?

Rack and pinion systems find extensive use in various industries where precise linear motion is required. These mechanisms are valued for their efficiency, reliability, and ability to convert rotational motion into linear motion. Here’s a detailed explanation of the industries in which rack and pinion systems are commonly used:

- Automotive Industry: Rack and pinion systems are widely employed in the automotive industry for steering systems. They are used in passenger cars, commercial vehicles, and other automotive applications to provide smooth and responsive steering control.

- Machinery and Manufacturing: Rack and pinion systems are commonly found in machinery and manufacturing applications. They are utilized in CNC machines, industrial automation systems, packaging machinery, material handling equipment, and assembly line systems to enable precise linear motion for various processes.

- Robotics and Automation: Rack and pinion systems play a crucial role in the robotics and automation industry. They are used in robotic arms, manipulators, joint mechanisms, and linear actuators to provide controlled linear motion for tasks such as lifting, extending, and positioning.

- Construction and Infrastructure: Rack and pinion systems are utilized in the construction and infrastructure sectors. They are commonly found in construction machinery like cranes and lifts, enabling vertical movement and precise positioning of heavy loads.

- Entertainment and Stage: Rack and pinion systems are widely used in the entertainment industry, particularly in stage and theater equipment. They are employed in moving platforms, scenery automation, and lifting mechanisms to facilitate controlled and smooth movement during performances.

- Printing and Packaging: Rack and pinion systems are commonly utilized in the printing and packaging industry. They are found in digital printers, large-format plotters, and packaging machinery, providing the necessary linear motion for accurate printing and packaging processes.

- Transportation and Logistics: Rack and pinion systems are employed in transportation and logistics applications. They are used in elevators, escalators, and material handling systems, enabling vertical movement, efficient transportation, and precise positioning of goods and people.

- Medical and Healthcare: Rack and pinion systems find application in the medical and healthcare industry. They are used in medical devices, hospital equipment, and diagnostic machinery, providing controlled linear motion for tasks such as patient positioning and sample handling.

- Agriculture and Farming: Rack and pinion systems are utilized in the agriculture and farming sector. They can be found in agricultural machinery like harvesters and sprayers, facilitating controlled linear motion for various farming processes.

These are just a few examples of industries where rack and pinion systems are commonly used. Their versatility, precision, and reliability make them suitable for a wide range of applications that require linear motion conversion.

editor by Dream 2024-05-16