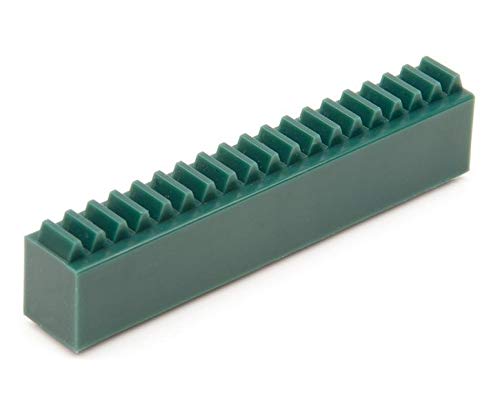

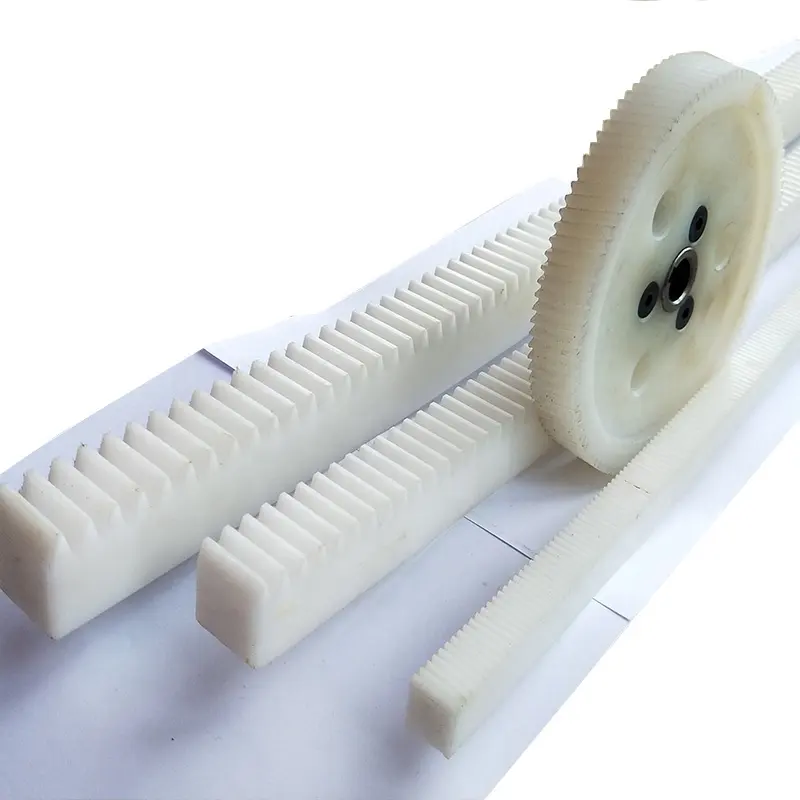

Product Description

Features

1. Available in sizes in Module1.5/2/3/4/5/6/7/8/9/10

2. Repeatability of up to ± 0.01mm

3. Powerful rack and pinion drives for reliable movements.

4. Extremely compact frame with high inherent stiffness

5. It is designed for high-temperature resistance, long service life.

6. Rigidness improved, Smaller size, Easy to maintain, Improve accuracy, Easy assemble, etc.

Operation

1. The operation conditions need to be within the rated values as shown in the technical information.

2. Avoid dust, debris, and any foreign objects from entering the rack and pinion return system.

3. The operational temperature should be under 80 ºC. In high-temperature environments above 80ºC.

4. If the product can be used in a special environment, such as vacuum, vibration,

clean room, corrosive chemicals, organic solvents, extremely high or low temperatures, humidity, liquid splashes,

oil drops or mist, high salt, heavy load, vertical or cantilever installations. Please Confirm first with TOCO.

5. For vertical installations, when loaded, there is a possibility that the slider may fall. We recommend adding

proper braking and ensure functionality before the operation.

Maintenance

1. Lubricate the product before the initial use. Note the type of grease used and avoid mixing different types together.

2. For normal operating conditions, it is recommended to check the operation every 100km, clean and supply grease CHINAMFG the rack and pinion.

| Brand | TOCO |

| Model | Rack and pinion |

| Size customize | Module1.5/2/3/4/5/6/7/8/9/10 |

| HS-CODE | 8483900090 |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, Western Union |

| Production lead time | 15 business days for sample, 35 days for the bulk |

| Keyword | Rack and pinion |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

Catalogs

Package & Shipping

1.Package: Carton or wooden case.

2.Delivery time: 15 days after receiving payment.

3.Shipping: by express (DHL, TNT, FedEx, etc.) or by sea.

TOCO Exhibition

ZheJiang brand registered trademark, High-Tech Enterprise, letter patents, and ISO.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Laser Cutting Machines |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Ground or Milled |

| Toothed Portion Shape: | Straight or Helical |

| Material: | S45c or Scm440 |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does the design of the rack and pinion affect its performance?

The design of the rack and pinion plays a crucial role in determining its performance characteristics and overall effectiveness. Various design factors influence the functionality, efficiency, and reliability of the rack and pinion system. Here’s a detailed explanation of how the design aspects affect the performance of a rack and pinion:

- Tooth Profile: The tooth profile of the rack and pinion has a significant impact on the system’s performance. Different tooth profiles, such as straight, helical, or involute, offer varying benefits in terms of load distribution, efficiency, backlash reduction, and quiet operation. The selection of the tooth profile is based on factors such as the application requirements, load capacity, speed, and desired smoothness of motion.

- Module and Pitch: The module and pitch of the rack and pinion refer to the size and spacing of the teeth. These parameters affect the system’s ability to transmit forces efficiently and accurately. A finer module and pitch provide smoother motion and higher precision but may have limitations in terms of load capacity. Coarser module and pitch are suitable for higher load applications but might result in slightly rougher motion.

- Material Selection: The choice of materials for the rack and pinion is critical for performance and durability. The materials need to have sufficient strength, wear resistance, and fatigue resistance to withstand the operating conditions and loads. Common materials used for rack and pinion include steel alloys, stainless steel, and specialized alloys. The selection depends on factors such as load requirements, environmental conditions, and the desired service life of the system.

- Lubrication: Proper lubrication is essential for optimal performance and longevity of the rack and pinion system. The design should facilitate efficient lubricant distribution to minimize friction, wear, and heat generation. Lubrication considerations include factors such as the lubricant type, method of application, and frequency of maintenance. Inadequate lubrication can lead to increased friction, reduced efficiency, and premature failure of the system.

- Backlash Control: Backlash refers to the play or clearance between the teeth of the rack and pinion. The design should aim to minimize backlash to ensure accurate and precise motion. Backlash can be controlled through various design features, such as tooth modifications, preloading mechanisms, or anti-backlash devices. Minimizing backlash is crucial in applications that require high positional accuracy and repeatability.

- Mounting and Alignment: The design should consider proper mounting and alignment of the rack and pinion system. Accurate alignment ensures smooth and efficient power transmission, reduces wear, and minimizes the risk of premature failure. The design should incorporate features that facilitate easy and precise mounting, such as alignment guides, mounting holes, or adjustable components.

- Load Capacity and Stiffness: The design should be optimized to handle the anticipated load capacity and provide sufficient stiffness to resist deflection or deformation under load. Factors such as the size and cross-section of the rack, tooth geometry, and material selection influence the system’s load-bearing capability and overall rigidity. A well-designed rack and pinion should maintain stability and accuracy, even under high loads.

- Noise and Vibration: The design should address noise and vibration considerations to ensure smooth and quiet operation. Features such as tooth profile modifications, surface treatments, or dampening mechanisms can be incorporated to reduce noise and vibration levels. This is particularly important in applications where noise reduction is crucial, such as precision equipment or noise-sensitive environments.

By carefully considering these design factors, engineers can optimize the performance of rack and pinion systems for specific applications. The appropriate design choices lead to improved efficiency, accuracy, durability, and overall reliability of the rack and pinion, enhancing its performance in various industrial and mechanical systems.

How do rack and pinion systems contribute to precise motion control?

Rack and pinion systems play a crucial role in achieving precise motion control in various applications. The inherent design and characteristics of rack and pinion mechanisms contribute to their ability to provide accurate and reliable motion control. Here’s a detailed explanation:

1. Direct and Efficient Power Transmission: Rack and pinion systems offer direct power transmission, meaning there are no intermediate components or linkages between the input and output. This direct connection allows for efficient power transfer without significant energy losses. As a result, the motion control system can respond quickly and accurately to input commands, enabling precise control over the position, speed, and acceleration of the driven load.

2. High Mechanical Advantage: Rack and pinion systems provide a mechanical advantage, especially in applications where linear force or torque needs to be converted. The gear ratio of the system determines the mechanical advantage, allowing for amplification or reduction of the input force or torque. By adjusting the gear ratio, the system can be optimized to achieve the desired level of precision and force transmission. The mechanical advantage enhances the system’s ability to overcome friction, resist external disturbances, and maintain positional accuracy.

3. Minimal Backlash: Backlash refers to the slight clearance or play between the teeth of the gears in a mechanical system. Rack and pinion systems are designed to minimize backlash, ensuring precise and repeatable motion control. The tight engagement of the gear teeth in a rack and pinion mechanism reduces backlash, resulting in minimal lost motion and improved accuracy. This characteristic is particularly important in applications that require precise positioning, such as CNC machines, robotics, or optical equipment.

4. Smooth and Continuous Motion: Rack and pinion systems can provide smooth and continuous motion due to the constant contact between the gear teeth. The teeth on the pinion gear mesh with the teeth along the rack’s length, resulting in a continuous transfer of motion. This continuous contact helps to eliminate jerks, vibrations, or hysteresis that could affect the precision of the motion control system. The smooth and continuous motion is vital for applications where precise speed control or smooth trajectory tracking is required.

5. High Positional Accuracy: Rack and pinion systems excel at achieving high positional accuracy. The linear nature of the motion provided by the rack allows for precise control over the position of the driven load. Combined with low backlash, the system can accurately maintain the desired position without significant deviation. This level of positional accuracy is critical in applications such as CNC machining, 3D printing, or metrology, where tight tolerances and precise positioning are essential.

6. Scalability and Flexibility: Rack and pinion systems offer scalability and flexibility, making them suitable for a wide range of applications. They can be designed and implemented in various sizes and configurations to accommodate different load capacities, travel distances, and speed requirements. The modular nature of rack and pinion systems allows for easy integration into different mechanical systems, making them adaptable to diverse motion control applications.

In conclusion, rack and pinion systems contribute to precise motion control through their direct power transmission, high mechanical advantage, minimal backlash, smooth and continuous motion, high positional accuracy, and scalability. These characteristics make rack and pinion mechanisms a popular choice in numerous industries, including robotics, automation, manufacturing, and automotive, where precise and reliable motion control is vital.

In which industries are rack and pinion systems commonly used?

Rack and pinion systems find extensive use in various industries where precise linear motion is required. These mechanisms are valued for their efficiency, reliability, and ability to convert rotational motion into linear motion. Here’s a detailed explanation of the industries in which rack and pinion systems are commonly used:

- Automotive Industry: Rack and pinion systems are widely employed in the automotive industry for steering systems. They are used in passenger cars, commercial vehicles, and other automotive applications to provide smooth and responsive steering control.

- Machinery and Manufacturing: Rack and pinion systems are commonly found in machinery and manufacturing applications. They are utilized in CNC machines, industrial automation systems, packaging machinery, material handling equipment, and assembly line systems to enable precise linear motion for various processes.

- Robotics and Automation: Rack and pinion systems play a crucial role in the robotics and automation industry. They are used in robotic arms, manipulators, joint mechanisms, and linear actuators to provide controlled linear motion for tasks such as lifting, extending, and positioning.

- Construction and Infrastructure: Rack and pinion systems are utilized in the construction and infrastructure sectors. They are commonly found in construction machinery like cranes and lifts, enabling vertical movement and precise positioning of heavy loads.

- Entertainment and Stage: Rack and pinion systems are widely used in the entertainment industry, particularly in stage and theater equipment. They are employed in moving platforms, scenery automation, and lifting mechanisms to facilitate controlled and smooth movement during performances.

- Printing and Packaging: Rack and pinion systems are commonly utilized in the printing and packaging industry. They are found in digital printers, large-format plotters, and packaging machinery, providing the necessary linear motion for accurate printing and packaging processes.

- Transportation and Logistics: Rack and pinion systems are employed in transportation and logistics applications. They are used in elevators, escalators, and material handling systems, enabling vertical movement, efficient transportation, and precise positioning of goods and people.

- Medical and Healthcare: Rack and pinion systems find application in the medical and healthcare industry. They are used in medical devices, hospital equipment, and diagnostic machinery, providing controlled linear motion for tasks such as patient positioning and sample handling.

- Agriculture and Farming: Rack and pinion systems are utilized in the agriculture and farming sector. They can be found in agricultural machinery like harvesters and sprayers, facilitating controlled linear motion for various farming processes.

These are just a few examples of industries where rack and pinion systems are commonly used. Their versatility, precision, and reliability make them suitable for a wide range of applications that require linear motion conversion.

editor by Dream 2024-05-07