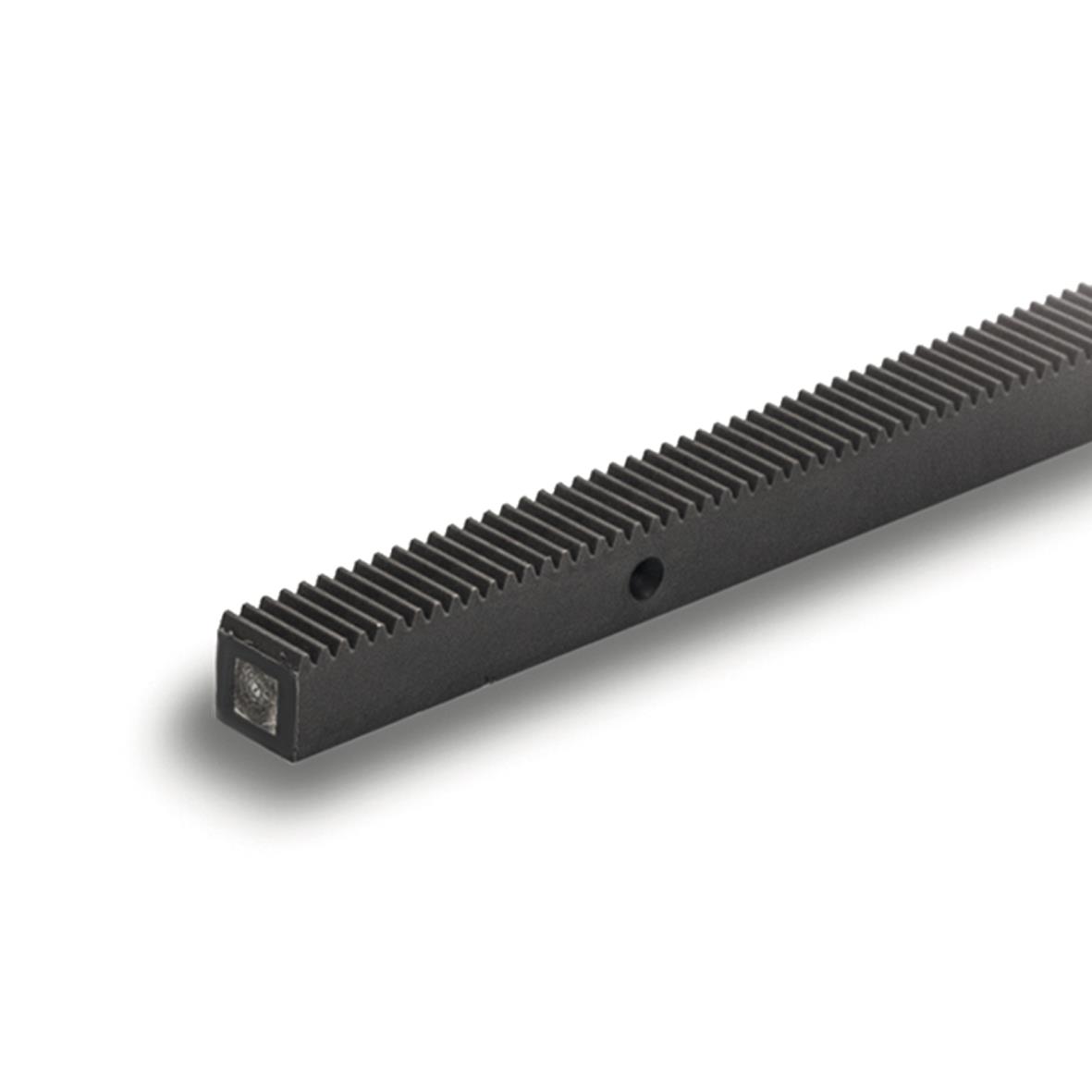

Product Description

Features

1. Available in sizes in Module1.5/2/3/4/5/6/7/8/9/10

2. Repeatability of up to ± 0.01mm

3. Powerful rack and pinion drives for reliable movements.

4. Extremely compact frame with high inherent stiffness

5. It is designed for high-temperature resistance, long service life.

6. Rigidness improved, Smaller size, Easy to maintain, Improve accuracy, Easy assemble, etc.

Operation

1. The operation conditions need to be within the rated values as shown in the technical information.

2. Avoid dust, debris, and any foreign objects from entering the rack and pinion return system.

3. The operational temperature should be under 80 ºC. In high-temperature environments above 80ºC.

4. If the product can be used in a special environment, such as vacuum, vibration,

clean room, corrosive chemicals, organic solvents, extremely high or low temperatures, humidity, liquid splashes,

oil drops or mist, high salt, heavy load, vertical or cantilever installations. Please Confirm first with TOCO.

5. For vertical installations, when loaded, there is a possibility that the slider may fall. We recommend adding

proper braking and ensure functionality before the operation.

Maintenance

1. Lubricate the product before the initial use. Note the type of grease used and avoid mixing different types together.

2. For normal operating conditions, it is recommended to check the operation every 100km, clean and supply grease CHINAMFG the rack and pinion.

| Brand | TOCO |

| Model | Rack and pinion |

| Size customize | Module1.5/2/3/4/5/6/7/8/9/10 |

| HS-CODE | 8483900090 |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, Western Union |

| Production lead time | 15 business days for sample, 35 days for the bulk |

| Keyword | Rack and pinion |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

Catalogs

Package & Shipping

1.Package: Carton or wooden case.

2.Delivery time: 15 days after receiving payment.

3.Shipping: by express (DHL, TNT, FedEx, etc.) or by sea.

TOCO Exhibition

ZheJiang brand registered trademark, High-Tech Enterprise, letter patents, and ISO.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Laser Cutting Machines |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Ground or Milled |

| Toothed Portion Shape: | Straight or Helical |

| Material: | S45c or Scm440 |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does a rack and pinion handle variations in load capacity and speed?

A rack and pinion system is designed to handle variations in load capacity and speed effectively. These mechanisms are capable of accommodating different operating conditions and adjusting to changes in load and speed. Here’s a detailed explanation of how a rack and pinion handles variations in load capacity and speed:

Load Capacity:

Rack and pinion systems can handle variations in load capacity due to their toothed engagement and distributed load-bearing capabilities. The teeth on the rack and pinion distribute the load evenly across the contact area, allowing for the transmission of substantial forces. As the load capacity increases, the teeth and the structure of the rack and pinion are designed to withstand the additional load without compromising the system’s integrity. This ensures that the rack and pinion can handle a wide range of load capacities, from light loads to heavy loads, while maintaining reliable and efficient linear motion.

Speed:

Rack and pinion systems can also accommodate variations in speed. The speed at which the rack and pinion operates can be adjusted based on the rotational speed of the pinion. By changing the rotational speed of the pinion, the linear speed of the rack can be controlled. This allows for flexibility in adapting to different speed requirements in various applications. Whether it’s a high-speed application that requires rapid linear motion or a slower-speed application that demands precise positioning, the rack and pinion system can be adjusted accordingly to achieve the desired speed.

It’s worth noting that the design and selection of the rack and pinion system play a crucial role in handling load capacity and speed variations. Factors such as the tooth profile, material selection, lubrication, and system layout are taken into consideration to ensure optimal performance under different operating conditions.

In summary, a rack and pinion system handles variations in load capacity by distributing the load evenly across the teeth, allowing for reliable transmission of forces. It accommodates changes in speed by adjusting the rotational speed of the pinion, thereby controlling the linear speed of the rack. These capabilities make rack and pinion systems versatile and adaptable to a wide range of load and speed requirements in different applications.

Can rack and pinion mechanisms be used for both rotary and linear motion?

Yes, rack and pinion mechanisms can be utilized for both rotary and linear motion. The primary function of a rack and pinion system is to convert rotational motion into linear motion or vice versa. Here’s a detailed explanation:

When a pinion gear, which is a small gear with teeth, meshes with a straight bar called a rack, it enables the transformation of rotary motion into linear motion. As the pinion gear rotates, it causes the rack to move linearly along its length. This linear motion can be utilized in various applications, such as in steering systems, linear actuators, or machine tools.

Conversely, a rack and pinion mechanism can also convert linear motion into rotary motion. In this case, the linear movement of the rack is used to rotate the pinion gear. This configuration is often employed in applications where linear force or displacement needs to be translated into rotational motion, such as in power steering systems or rotary indexing mechanisms.

The versatility of rack and pinion mechanisms lies in their ability to efficiently transmit motion and power in both directions. The system’s simplicity and mechanical advantage make it suitable for a wide range of applications requiring precise positioning, high force transmission, or smooth motion control.

It is important to note that the specific design and implementation of a rack and pinion system may differ depending on whether it is intended for rotary-to-linear or linear-to-rotary motion conversion. Factors such as the size and shape of the rack and pinion components, the gear ratio, and the supporting structure may vary accordingly. However, the fundamental principle of converting rotational and linear motion remains the same.

Overall, rack and pinion mechanisms offer a versatile solution for converting motion between rotary and linear forms, making them widely used in numerous industrial, automotive, and mechanical applications.

What are the advantages of using rack and pinion for linear motion?

Rack and pinion systems offer several advantages when it comes to achieving linear motion. These mechanisms are widely used due to their efficiency, precision, and reliability. Here’s a detailed explanation of the advantages of using rack and pinion for linear motion:

- High Efficiency: Rack and pinion systems are known for their high efficiency in converting rotational motion into linear motion. The meshing of the teeth on the rack and pinion allows for a direct transfer of power, minimizing energy losses and ensuring efficient motion conversion.

- Precise Positioning: Rack and pinion mechanisms provide precise positioning capabilities. The teeth on the rack and pinion allow for accurate and repeatable linear motion, making them suitable for applications that require precise positioning, such as CNC machines, robotics, and automated systems.

- Smooth and Controlled Motion: Rack and pinion systems offer smooth and controlled linear motion. The engagement between the teeth of the rack and pinion ensures a continuous and stable transfer of motion, resulting in smooth and reliable movement without backlash or play.

- Compact Design: Rack and pinion mechanisms have a compact design, making them suitable for applications with space constraints. The linear motion is achieved along the length of the rack, allowing for a linear displacement without the need for additional mechanisms or complex setups.

- Cost-Effective: Rack and pinion systems are often cost-effective compared to other linear motion mechanisms. They have a relatively simple design and can be manufactured using common materials, which contributes to their affordability and widespread availability.

- High Load Capacity: Rack and pinion systems can handle high load capacities. The teeth on the rack and pinion distribute the load evenly, allowing for the transmission of substantial forces and enabling the handling of heavy loads in various applications.

- Durable and Reliable: Rack and pinion mechanisms are known for their durability and reliability. When properly designed and maintained, they can withstand heavy use, harsh environments, and demanding operating conditions, ensuring long-term functionality and minimal downtime.

- Wide Range of Applications: Rack and pinion systems have a wide range of applications across different industries. Their versatility makes them suitable for use in automotive steering systems, CNC machines, robotics, elevators, stage equipment, printing machinery, and many other mechanical systems.

These advantages make rack and pinion systems a popular choice for achieving linear motion in various applications. Whether it’s for precision positioning, efficient power transmission, or smooth motion control, rack and pinion mechanisms offer numerous benefits that contribute to their widespread use.

editor by Dream 2024-05-08